Ndị otu anyị nke Metallurgists na Injinia ga-ahụ na ị nwere ntụkwasị obi zuru oke ngwaahịa enyere.

Nnyocha ụlọ nyocha na nyocha anyị na-enye Metallographic, Mechanical, Dimensional, Chemical Chemicals, were gabazie.

Anyị ga-akwalite Nnyocha na nnwale ọchịchị iji mezuo ihe ị chọrọ. Atụmatụ ogo anyị dị iche iche site na nyocha oge niile na nyocha ederede na traceability.

Anyị na-enye ụlọ zuru oke nke ule na-ebibi ihe na enweghị mbibi gụnyere:

1. 1. Co-Ordinate Atụ Machine CMM

2. Redio

3. Nnyocha Ngwá Ọrụ Magnetik

4. Nnyocha Penetrant Die

5. Nyocha Spectrographic Chemical Analysis

6. Nnwale ule

7. Mkpakọ Ule

8. Bend Test

9. Nnwale ule

10. Metallografi

Nnyocha ihe mejupụtara Chemical

Mgbe akụrụngwa gbazee n’ime nchara gbazee. Anyị na-eji spectrometer nwalee ihe nke nchara nchara tupu ị wụọ iji jide n'aka na ngwaahịa ndị ahụ nwere ọkwa nchara ziri ezi.

Nnyocha Dimension

Nnyocha nyocha dabere na eserese iji tụọ ma nkedo nkedo dị n'ime oke ndidi, iji chọta njehie nke ọdịdị na akụkụ. Tụkwasị na nke ahụ, a ga-eji nlezianya nyochaa izi ezi nke ịkpụzi ọnọdụ datum, nkesa mmachi akpa na ntụgharị mgbidi mgbidi.

Nnyocha Ngwá Ọrụ Magnet (MPI)

MPI bụ usoro nyocha nke na-enweghị mbibi (NDT) maka ịchọpụta ala na nkwụsị miri emi na-akwụsị na ihe ndị na-emepụta ferromagnetic dịka ígwè, nickel, cobalt, na ụfọdụ alloys ha. Usoro ahụ na-etinye magnetik n'ime akụkụ ahụ. Enwere ike ime ka mpempe ihe site na nju. Direct magnetization na-eme mgbe eletrik na-agafe ihe nyocha ma na-emepụta magnetik na ihe ahụ. Ntugharị na-apụtaghị ìhè na-apụta mgbe ọ na-adịghị ike ọkụ eletrik gafere site n'ihe nyocha ahụ, mana a na-etinye oghere magnetik site na mpụga. Ihe ndọba magnetik na-adabere na ntụziaka nke ọkụ eletrik, nke nwere ike ịbụ nke ọzọ (AC) ma ọ bụ ụdị ụfọdụ nke ugbu a (DC) (AC edozi).

Nyocha nke Ultrasonic (UT)

UT bụ ezinụlọ nke usoro nyocha na-enweghị mbibi na-adabere na mgbasa nke ebili mmiri ultrasonic na ihe ma ọ bụ ihe a nwalere. Na ngwa UT kachasị, ngwa ngwa ultrasonic pulse-ebili mmiri na etiti etiti sitere na 0.1-15 MHz, na oge ụfọdụ ruo 50 MHz, na-ebute n'ime ihe iji chọpụta ntụpọ dị n'ime ma ọ bụ iji mara ihe. Otu ihe omuma atu bu ihe omimi nke ultrasonic, nke na-anwale ugwo nke ihe nlere, dika imaatu, iji nyochaa corrosion corrosion.

Ule siri ike

Isiike bụ ike nke ihe iji guzogide nrụgide nke ihe siri ike na ihu ha. Dị ka usoro ule dị iche iche si dị iche iche, enwere ike kewaa nkeji siri ike na Brinell ekweghị ekwe, Vickers hardness, Rockwell ekweghị ekwe, micro Vickers hardness, wdg. àgwà dị iche iche.

Nnwale Redio (RT)

(RT ma ọ bụ X-ray ma ọ bụ Gamma ray) bụ usoro nyocha anaghị emebi emebi (NDT) nke na-enyocha olu ihe atụ. Radiography (X-ray) na-eji ụzarị ọkụ na ụzarị ọkụ eme ihe iji mepụta redio nke ụdị, na-egosi mgbanwe ọ bụla na ọkpụrụkpụ, ntụpọ (n'ime na mpụga), yana nkọwa nzukọ iji hụ na ọrụ kacha mma na ọrụ gị.

Ule Ngwongwo Mechanical

Companylọ ọrụ anyị nwere 200 tọn na 10 tọn tensile igwe. Enwere ike iji ya nwalee akụrụngwa nke ụfọdụ ngwaahịa pụrụ iche.

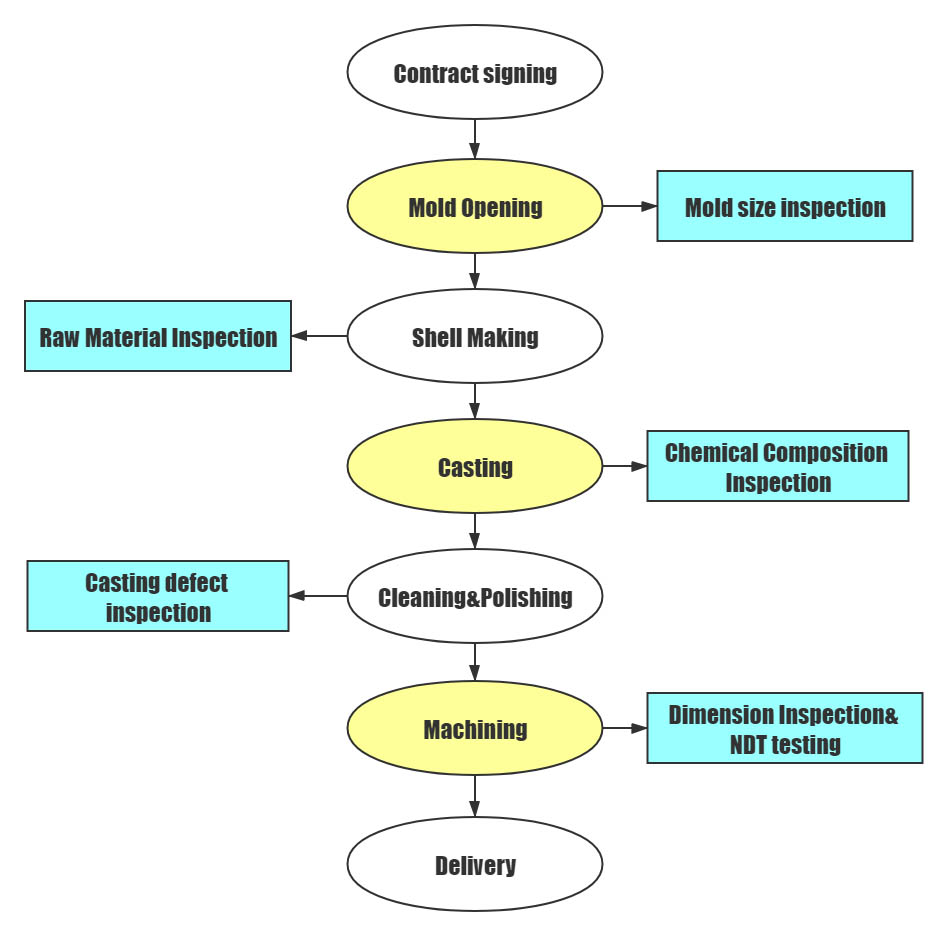

Chart Nnyocha Ntugharị

Ọdịdị dị elu, ntụpọ efu bụ ebumnuche anyị na-achụ mgbe niile. Nkwenye nke ndị ahịa bụ ihe na-eme ka anyị nwee ọganihu na-aga n'ihu. Mgbe anyị nwesịrị ihe karịrị afọ iri nke azụmahịa mba ụwa, anyị emeela mgbanwe dị mma na njikwa njikwa ihe nkedo. N'afọ ndị na-adịbeghị anya, anyị abawanyela ọtụtụ ngwa nyocha dị elu dị ka igwe 200/10 Tons Tensile, Ngwa nyocha nke Ultrasonic, akụrụngwa nnwale magnetik, X-ray flaw detection equipment, Two chemical mejupụtara analyzers, Rockwell ekweghị ekwe tester na na .